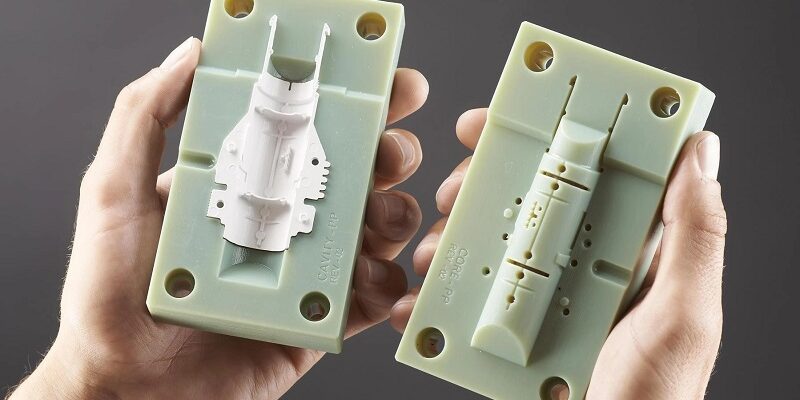

Prototype injection molding is a process used to quickly create a small number of plastic parts for testing, design validation, and pre-production purposes. It uses the same general principles as traditional injection molding, where melted plastic is injected into a mold to form a specific shape. However, the key difference is that prototype molding focuses on speed and flexibility over long-term durability and mass production.

For companies developing a new product, having a few functional prototypes that closely mimic the final product is incredibly valuable. It helps engineers catch design flaws early, test the fit and function of parts, and show physical models to clients or investors.

Why Use Prototype Injection Molding?

When developing a new plastic product, waiting until mass production to spot problems can be costly. Prototype injection molding solves this by giving teams a low-cost, low-risk way to evaluate a design before committing to full-scale tooling. This can save thousands of dollars in rework and help speed up time to market.

Unlike 3D printing or CNC machining, prototype injection molding creates parts from the actual plastic materials that will be used in production. That means the prototypes can be tested in real-world conditions—heat, stress, flexibility, and more—to see how the final product will perform.

Benefits of Prototype Molding

- Faster Time to Market

With prototype molds, you can get functional parts in days or weeks instead of months. This faster turnaround means design teams can move quickly through multiple iterations and stay ahead of competitors.

- Cost-Effective Development

Full-scale production molds can cost tens of thousands of dollars. Prototype molds, often made from aluminum or other softer materials, are much more affordable—making them ideal for short runs and design trials.

- Real-World Testing

By using the same plastic material as the final product, teams can test things like strength, durability, and reaction to heat or chemicals. That kind of real-world validation is essential before committing to a final design.

- Improved Communication

Having a physical part in hand makes it easier to communicate with stakeholders, whether it’s your engineering team, marketing department, or external partners. Seeing and touching a prototype helps avoid misunderstandings and improves collaboration.

How the Process Works

The first step in prototype injection molding is designing a mold based on your 3D CAD model. A quick-turn mold, often made from aluminum, is then created. This mold may not be built for tens of thousands of cycles, but it will be accurate enough to produce functional parts.

Once the mold is ready, molten plastic is injected into it under pressure. After the plastic cools and solidifies, the mold is opened and the part is ejected. These parts can then be tested, assembled, or even shown to customers.

In some cases, changes to the prototype design may require adjustments to the mold. Because prototype molds are simpler and easier to modify than production molds, revisions can be made quickly—keeping your development process moving forward.

When Should You Use It?

Prototype injection molding is ideal for:

- Pre-production testing

- Design validation

- Market feedback before a product launch

- Low-volume product runs

- Bridge tooling before full-scale production

Startups, product developers, and engineers across industries—automotive, medical, consumer products—use prototype molding as part of their innovation process.

Final Thoughts

Prototype injection molding is a smart, efficient way to turn your product ideas into real, testable parts. It saves time, cuts costs, and gives you confidence before going into full production. Whether you’re refining a complex plastic component or testing a simple enclosure, this method helps you bring better products to market—faster.

If you’re developing something new and want to minimize risks, prototype injection molding could be the most practical step between concept and final production.

Comments